IX Components

IX Components

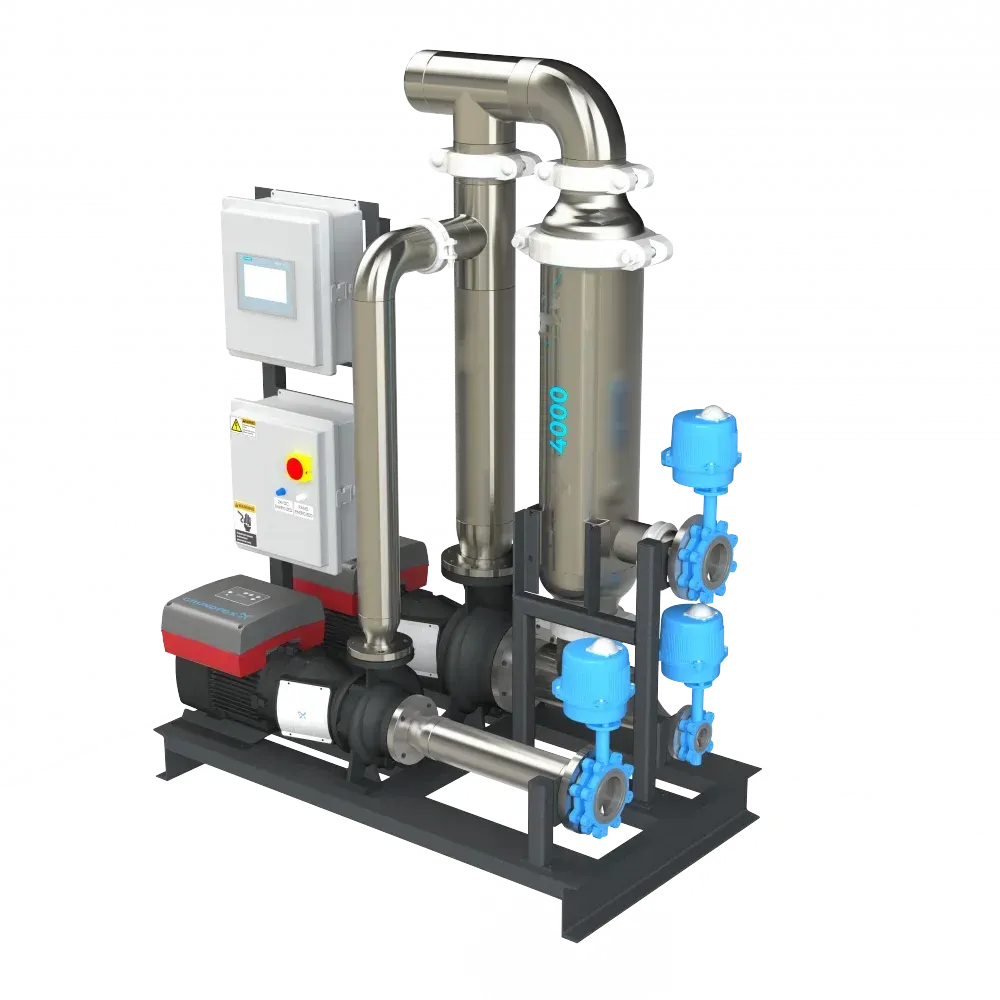

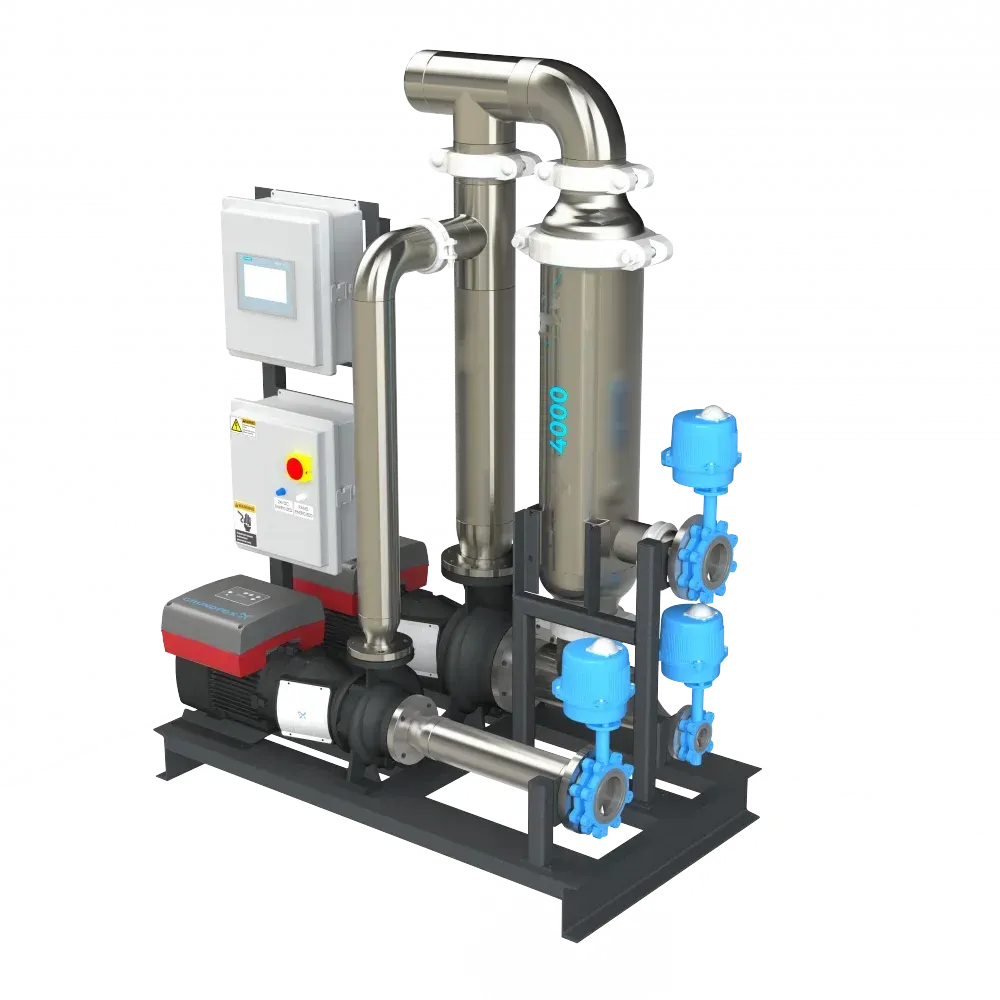

IX Water manufactures a moduler, scaleable machine for treating industrial wastewater.

The system is commercial application of technology developed at the USA Department of Energy’s Los Alamos National Laboratory, with additional engineering and technology from NASA, New Maxico Tech and the University of Texas.

IX Water manufactures a moduler, scaleable machine for treating industrial wastewater.

The system is commercial application of technology developed at the USA Department of Energy’s Los Alamos National Laboratory, with additional engineering and technology from NASA, New Maxico Tech and the University of Texas.

99.8% contaminant removal

50% or better cost savings

In situ rechargeable media

No chemical additives

No biologic decomposition ponds

Real-time treatment 10 min

Minimal power usage

Specific modules to solve specific problems

The IX Water Solution

The IX Water treatment train is a series of standardized, scalable modules that provide treatment specific to your needs without the cost and variability of a custom water treatment plant. These modules simply link together using standard fittings. Need additional treatment volume? Our modular design gives you virtually unlimited scalability. Select the modules you need to create a system right for you.

The key to IX Water effectiveness is reactors targeted just to specific contaminant classes.

Field re-chargeable media that lasts a year or more enables complete treatment at a much lower cost than traditional treatment, and even less cost than dumping the resource down a disposal well.

99.8% contaminant removal

50% or better cost savings

In situ rechargeable media

No chemical additives

No biologic decomposition ponds

Real-time treatment 10 min

Minimal power usage

Specific modules to solve specific problems

The IX Water Solution

The IX Water treatment train is a series of standardized, scalable modules that provide treatment specific to your needs without the cost and variability of a custom water treatment plant. These modules simply link together using standard fittings. Need additional treatment volume? Our modular design gives you virtually unlimited scalability. Select the modules you need to create a system right for you.

The key to IX Water effectiveness is reactors targeted just to specific contaminant classes.

Field re-chargeable media that lasts a year or more enables complete treatment at a much lower cost than traditional treatment, and even less cost than dumping the resource down a disposal well.

PartiClear™ Traps Suspended Solids and Separates Oil & Water:

1.Pressure-controlled feed-water enters the unit and the water velocity across the filter screen initiates cross-flow filtration.

2.The feed-water flow drives the cleaning brush assembly. activating the cleaning mechanisms within the filter which continuously clean the filter screen, minimizing cake buildup.

3.Solids enter the recirculation and solids collection chamber. Heavy solids remain in the collection chamber while other particles flow into the recirculation pipe which feeds back into the feed inlet feedwater flow.

4.Concentrated solids are purged periodically for dis or further processing.

Continuously cleaning, cross-flow filtration with forced settling and solids collection

Suspended solids, wax, bio-litter, fats, oils, and grease (FOG)

Long or short fibers; hair, lint, and algae • Simple, self-cleaning, automatic operation

Low maintenance and high uptime – no backwashing or excessive filter changes High water recovery; up to 99%

PartiClear™ Traps Suspended Solids and Separates Oil & Water:

1.Pressure-controlled feed-water enters the unit and the water velocity across the filter screen initiates cross-flow filtration.

2.The feed-water flow drives the cleaning brush assembly. activating the cleaning mechanisms within the filter which continuously clean the filter screen, minimizing cake buildup.

3.Solids enter the recirculation and solids collection chamber. Heavy solids remain in the collection chamber while other particles flow into the recirculation pipe which feeds back into the feed inlet feedwater flow.

4.Concentrated solids are purged periodically for dis or further processing.

Continuously cleaning, cross-flow filtration with forced settling and solids collection

Suspended solids, wax, bio-litter, fats, oils, and grease (FOG)

Long or short fibers; hair, lint, and algae • Simple, self-cleaning, automatic operation

Low maintenance and high uptime – no backwashing or excessive filter changes High water recovery; up to 99%

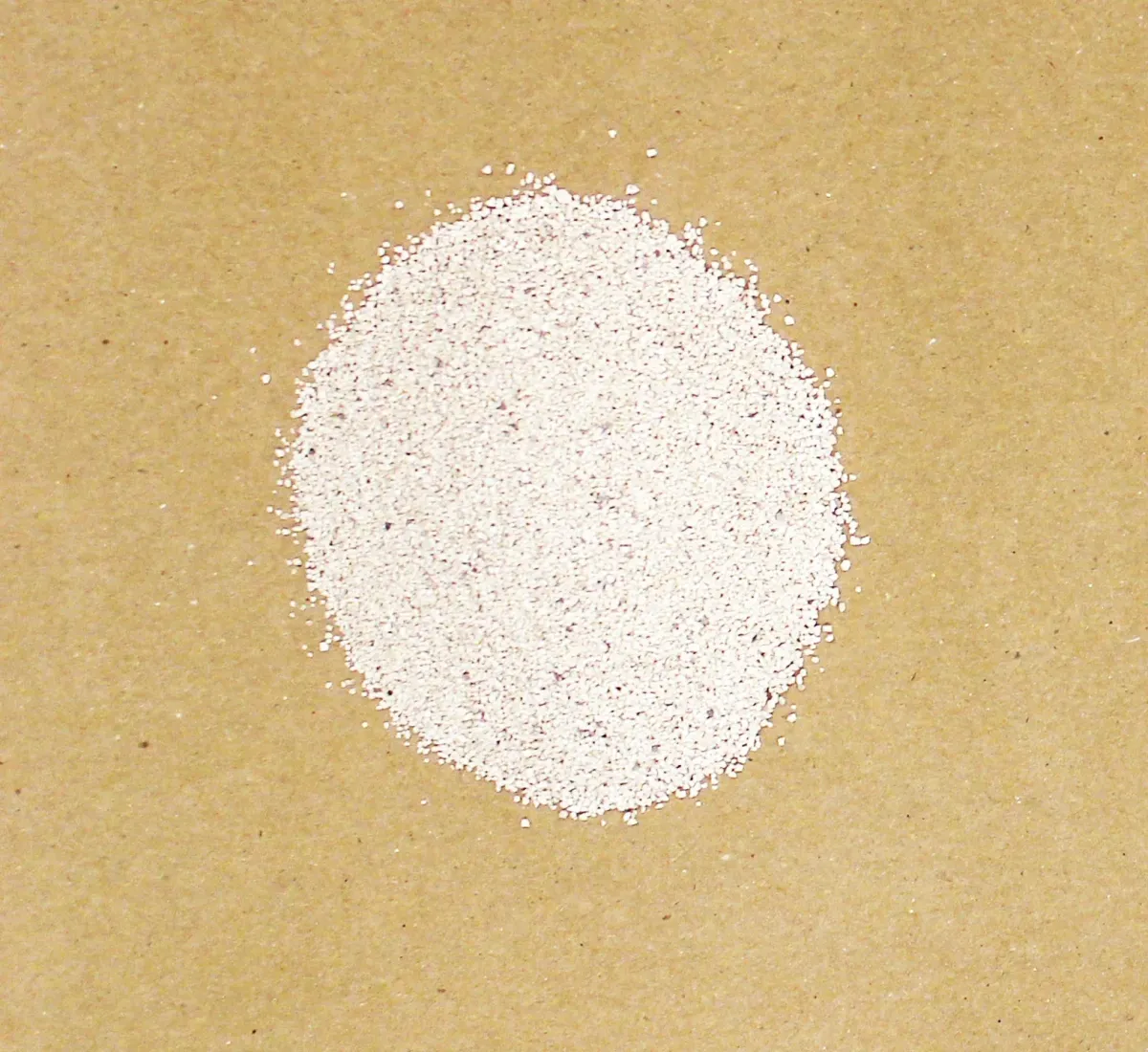

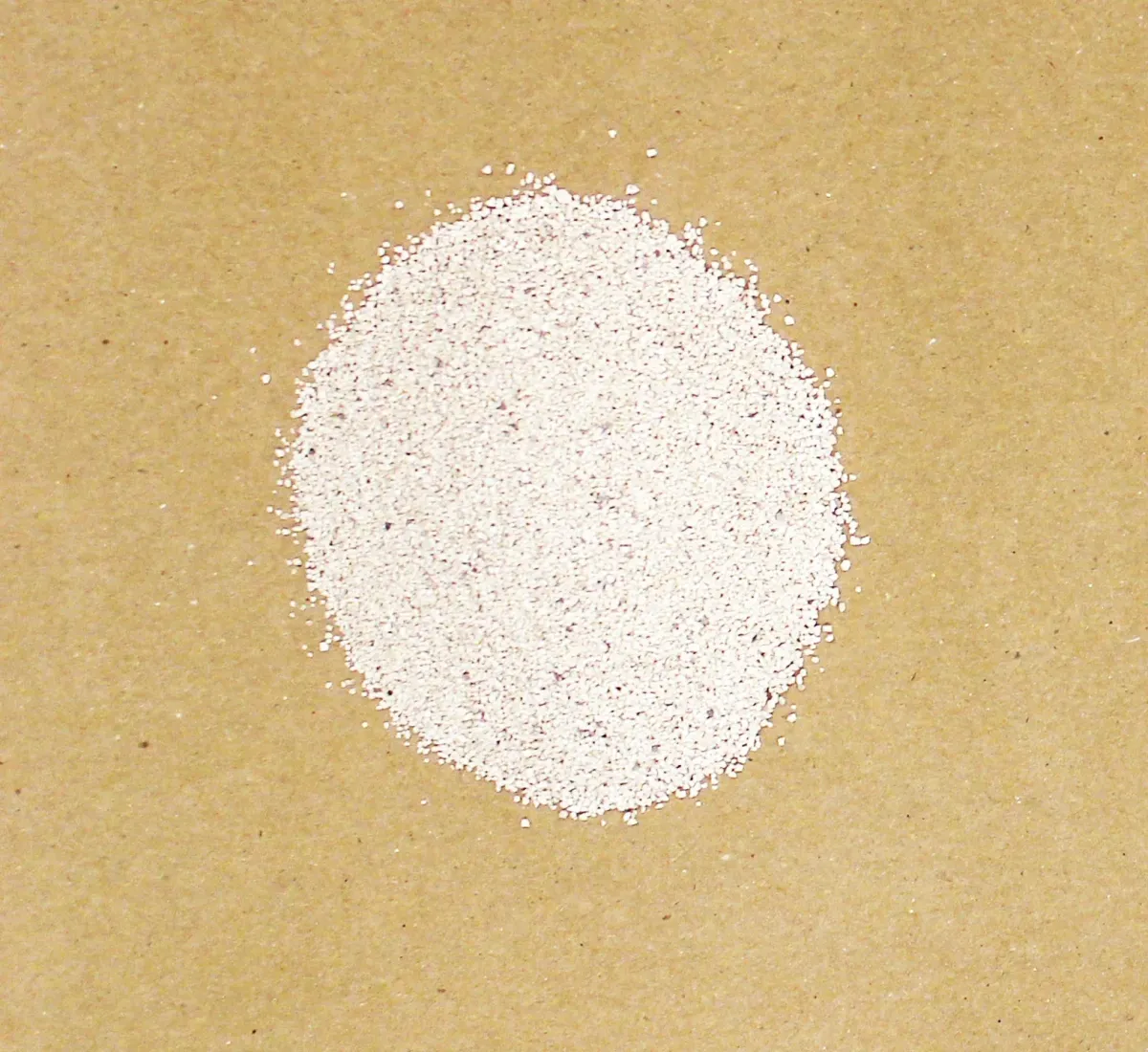

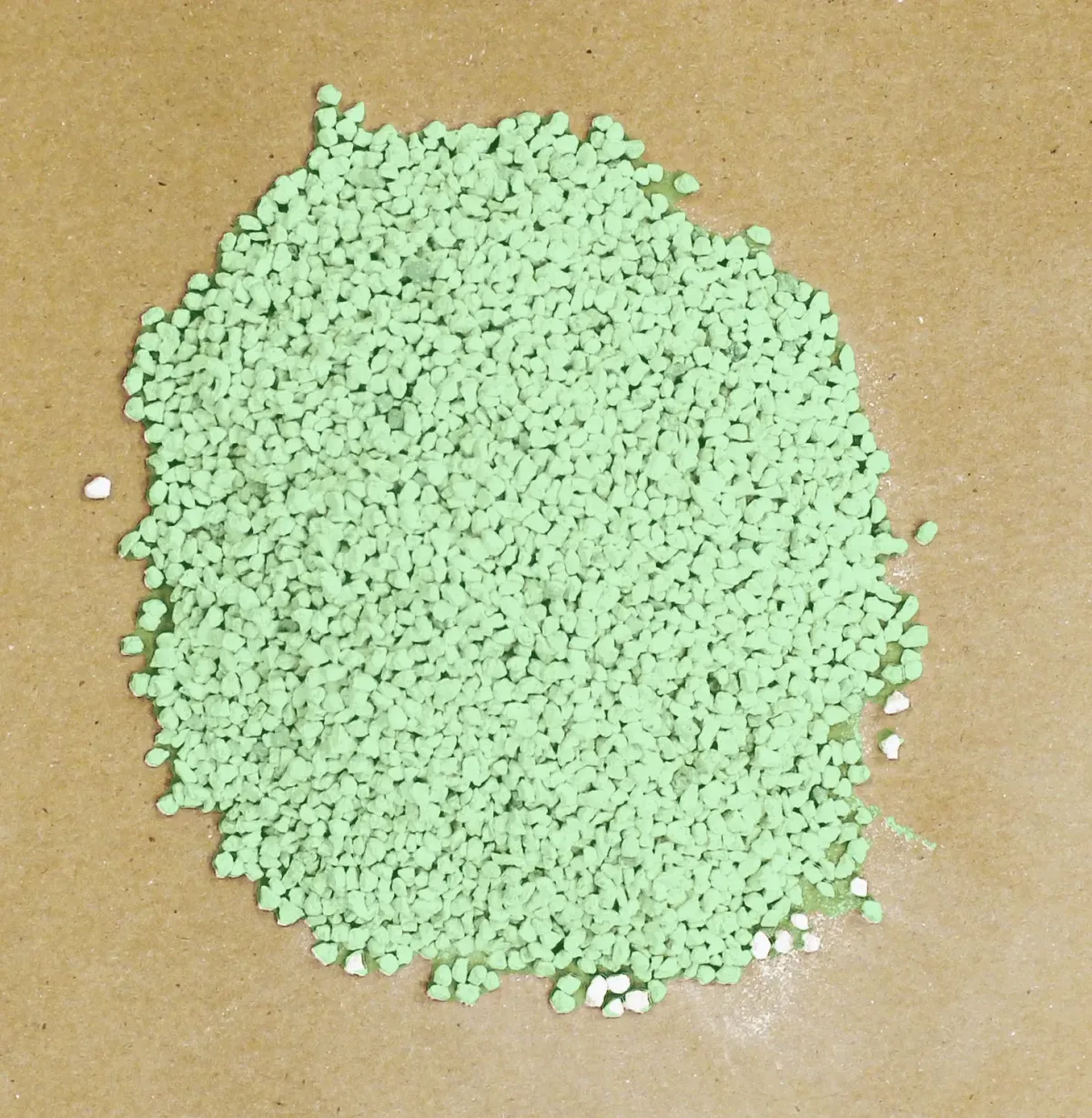

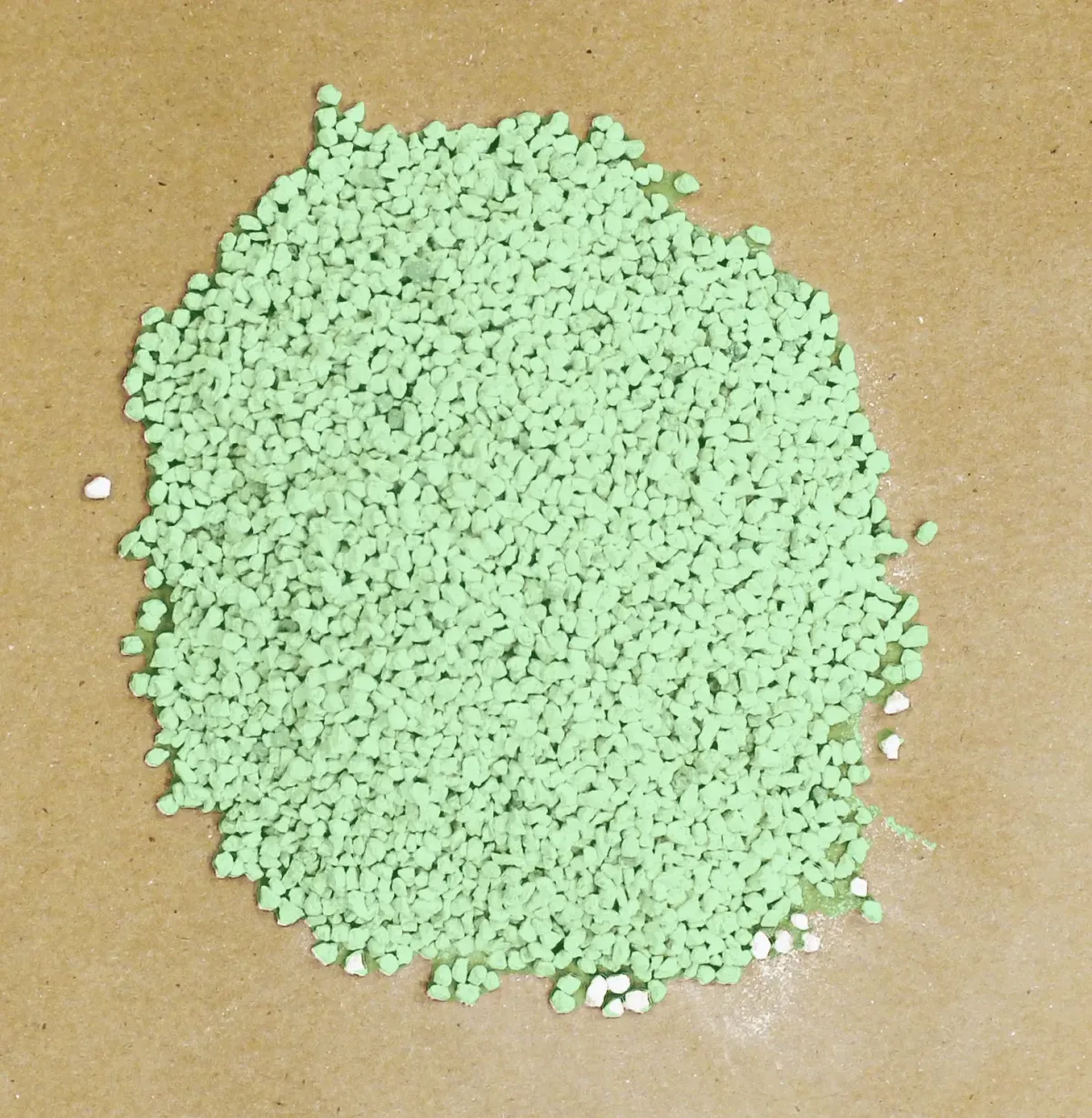

SULFUR CLEAR™ DESTROYS SULFIDE MOLECULES

Ix–SOX media enables chlorine cations, stabilized in various proprietary ways, to be coated onmineral media that instantaneously destroy Sulfide molecules by oxidation. The processproduces a small quantity ofinnocuous inorganic salts and eliminates disposal problems withoutraising issues of toxicity, corrosion, or environmental damage. The media is recharged in situusing sodium hypochlorite, and the media itself will last two to three years.

Periodic recharge of the media is accomplished with an integrated and automated backwash system.

No added chemicals

Complete oxidation of sulfides resulting in zero waste stream

Media lasts for years and is recharged in the reactor using household bleach

Follows PartiClear

SULFUR CLEAR™ DESTROYS SULFIDE MOLECULES

Ix–SOX media enables chlorine cations, stabilized in various proprietary ways, to be coated onmineral media that instantaneously destroy Sulfide molecules by oxidation. The processproduces a small quantity ofinnocuous inorganic salts and eliminates disposal problems withoutraising issues of toxicity, corrosion, or environmental damage. The media is recharged in situusing sodium hypochlorite, and the media itself will last two to three years.

Periodic recharge of the media is accomplished with an integrated and automated backwash system.

No added chemicals

Complete oxidation of sulfides resulting in zero waste stream

Media lasts for years and is recharged in the reactor using household bleach

Follows PartiClear

Wastewater is pumped into the bottom valve of the SulfurClear reactor tank at a rate of 70 gpm(for the IX Water 2500 Series) and rises through the media. Media contact of sulfur compounds inthe water are instantly oxidized and the treated water flows out the top reactor valve.

Wastewater is pumped into the bottom valve of the SulfurClear reactor tank at a rate of 70 gpm(for the IX Water 2500 Series) and rises through the media. Media contact of sulfur compounds inthe water are instantly oxidized and the treated water flows out the top reactor valve.

MetalClear™ Treats Metals, Metalloids, and Heavy Metals

MetalClear employs IxMZ-S, one of IX Water’s specialty formulated ‘sorption and ion exchange medias to effect metals removal. This media is long-lasting, low cost, and highly durable. The system itself is very low power, requiring only a feed pump, operating at ambient pressure, and the media is on-site regenerable with an integrated brine backwash.

Depending on input quality, high metal waste brine may be held to a volume of less than 1/1000th of flow volume. This waste can be safely disposed of along with reject brine from the site salt removal process, or evaporated and disposed of as solid waste.

No added chemicals

IxMZ-S media is used to trap dissolved metals in real-time

High water recovery; up to 99%+

Media lasts for a year with regeneration in situ using brine

MetalClear™ Treats Metals, Metalloids, and Heavy Metals

MetalClear employs IxMZ-S, one of IX Water’s specialty formulated ‘sorption and ion exchange medias to effect metals removal. This media is long-lasting, low cost, and highly durable. The system itself is very low power, requiring only a feed pump, operating at ambient pressure, and the media is on-site regenerable with an integrated brine backwash.

Depending on input quality, high metal waste brine may be held to a volume of less than 1/1000th of flow volume. This waste can be safely disposed of along with reject brine from the site salt removal process, or evaporated and disposed of as solid waste.

No added chemicals

IxMZ-S media is used to trap dissolved metals in real-time

High water recovery; up to 99%+

Media lasts for a year with regeneration in situ using brine

Targeted metals include: Aluminum, Antimony, Arsenic, Beryllium, Cadmium, Chromium, Copper, Iron, Lead, Manganese, Mercury, Nickel, Thallium, Uranium, and Zinc.

Targeted metals include: Aluminum, Antimony, Arsenic, Beryllium, Cadmium, Chromium, Copper, Iron, Lead, Manganese, Mercury, Nickel, Thallium, Uranium, and Zinc.

OrganiClear™ Destroys Hydrocarbons, VOCs, PAHs, and NPD

OrganiClear is IX Power Clean Water’s module for removing volatile and semi-volatile organic compounds (VOCs and SVOCs). Dissolved and emulsified organic hydrocarbons are trapped via adsorption1 and then converted to innocuous by-products (CO2 and water) via IxMZ media. These compounds include dissolved hydrocarbons (BTEX), polyaromatic hydrocarbons (PAHs), and NPD (naphthalenes, phenanthrenes, dibenzothiophenes).

No added chemicals

IxMZ traps VOCs and dissolved hydrocarbons

Complete destruction of contaminants without air emissions

High water recovery; up to 99%+

Media lasts for months and is recharged in the reactor via air stripping

Follows MetalClear

OrganiClear™ Destroys Hydrocarbons, VOCs, PAHs, and NPD

OrganiClear is IX Power Clean Water’s module for removing volatile and semi-volatile organic compounds (VOCs and SVOCs). Dissolved and emulsified organic hydrocarbons are trapped via adsorption1 and then converted to innocuous by-products (CO2 and water) via IxMZ media. These compounds include dissolved hydrocarbons (BTEX), polyaromatic hydrocarbons (PAHs), and NPD (naphthalenes, phenanthrenes, dibenzothiophenes).

No added chemicals

IxMZ traps VOCs and dissolved hydrocarbons

Complete destruction of contaminants without air emissions

High water recovery; up to 99%+

Media lasts for months and is recharged in the reactor via air stripping

Follows MetalClear

IxMZ used in OrganiClear is a specially manufactured clinoptilolite modified with an innocuous surfactant. This ensures not only the appropriate capture of organic hydrocarbons (including BTEX) but also ensures the media can be field recharged via air.

Periodic recharge of the media is accomplished with an integrated and automated air sparging system, where contaminants are trapped for disposal.

IxMZ used in OrganiClear is a specially manufactured clinoptilolite modified with an innocuous surfactant. This ensures not only the appropriate capture of organic hydrocarbons (including BTEX) but also ensures the media can be field recharged via air.

Periodic recharge of the media is accomplished with an integrated and automated air sparging system, where contaminants are trapped for disposal.

MetalClear++™ Treats Scalants

MetalClear++ employs IX Water’s specially formulated ion exchange medias to affect metals and scalant removal concurrently. This media was specifically designed to be long-lasting, low-cost, and highly durable. The system itself is very low power, requiring only a feed pump that operates at ambient pressure, and is on-site regenerable with brine.

Depending on regeneration technique, high metal waste brine may be held to a volume of less than 1/100th of flow volume. This waste can be safely disposed of along with reject brine from the system’s salt removal process, or evaporated and disposed of as solid waste.

No added chemicals

Ix media is used to trap scalants in real-time

High water recovery; up to 99%+

Media last for a year with regeneration in situ using brine

MetalClear++™ Treats Scalants

MetalClear++ employs IX Water’s specially formulated ion exchange medias to affect metals and scalant removal concurrently. This media was specifically designed to be long-lasting, low-cost, and highly durable. The system itself is very low power, requiring only a feed pump that operates at ambient pressure, and is on-site regenerable with brine.

Depending on regeneration technique, high metal waste brine may be held to a volume of less than 1/100th of flow volume. This waste can be safely disposed of along with reject brine from the system’s salt removal process, or evaporated and disposed of as solid waste.

No added chemicals

Ix media is used to trap scalants in real-time

High water recovery; up to 99%+

Media last for a year with regeneration in situ using brine

Targeted species include: magnesium, calcium, strontium, and barium.

Targeted species include: magnesium, calcium, strontium, and barium.

NORMClear™ Traps Radioactive Materials

NormClear is an IX Water component for the reduction and removal of NORM and TENORM from oil and gas produced water and industrial wastewaters. The technology employs a patent-pending tungstate based in-situ regenerable adsorption media.

NormClear is a low-energy and high throughput solution to all of industry’s NORM and TENORM removal needs.

No added chemicals

Complete trapping of NORM and TENORM materials

Media last for years and is recharged in the reactor

Location within the treatment train will depend on other contaminants in the wastewater

NORMClear™ Traps Radioactive Materials

NormClear is an IX Water component for the reduction and removal of NORM and TENORM from oil and gas produced water and industrial wastewaters. The technology employs a patent-pending tungstate based in-situ regenerable adsorption media.

NormClear is a low-energy and high throughput solution to all of industry’s NORM and TENORM removal needs.

No added chemicals

Complete trapping of NORM and TENORM materials

Media last for years and is recharged in the reactor

Location within the treatment train will depend on other contaminants in the wastewater

No added chemicals

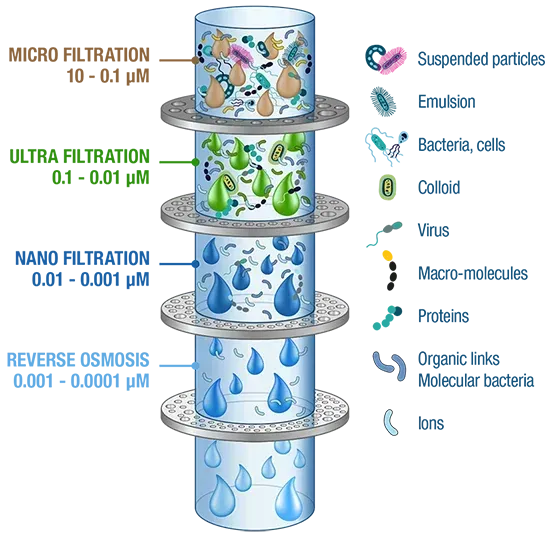

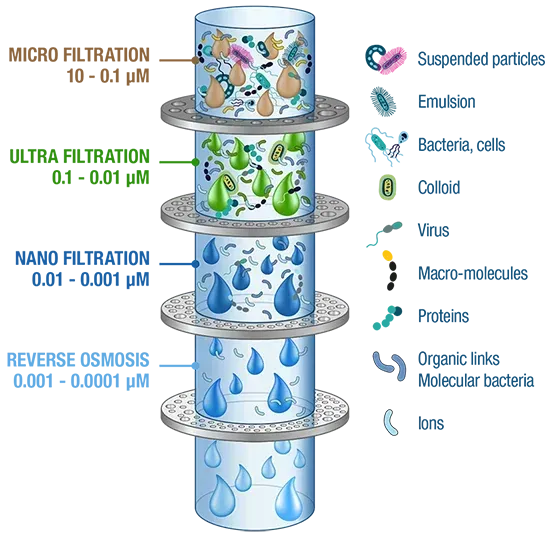

IX Water components provide for higher membrane-based water recovery at a much lower cost

SaltClear are optimized membrane and electrodialysis machines specifically designed to work within the IX Water Treatment Train

IX Water Component

SaltClear™ Concentrates salts and Lowers TDS

SaltClear is a family of machinery that concentrates salts and lowers total dissolved solids (TDS). The strength of these systems lies in the prior IX Water treatment steps. Membrane technologies, from reverse osmosis up to and including microfiltration, provide the final step in treating industrial wastewater.

The flexibility of SaltClear components provides the user the opportunity to fine-tune resulting water quality to reuse, recycle, or renew valuable water resources.

For Contact Us

Mail: [email protected]

Phone: +12023522138

17301 W Colfax Ave, Suite 110

, Golden, CO,80401

No added chemicals

IX Water components provide for higher membrane-based water recovery at a much lower cost

SaltClear are optimized membrane and electrodialysis machines specifically designed to work within the IX Water Treatment Train

IX Water Component

SaltClear™ Concentrates salts and Lowers TDS

SaltClear is a family of machinery that concentrates salts and lowers total dissolved solids (TDS). The strength of these systems lies in the prior IX Water treatment steps. Membrane technologies, from reverse osmosis up to and including microfiltration, provide the final step in treating industrial wastewater.

The flexibility of SaltClear components provides the user the opportunity to fine-tune resulting water quality to reuse, recycle, or renew valuable water resources.

For Contact Us

Mail: [email protected]

Phone: +13032779520

17301 W Colfax Ave, Suite 110

, Golden, CO,80401